First I'd like to point out the differences between the original Guider 2/2s, and the updated release of the 2s. Originally, FlashForge used one heatsink (the round bit with the fins) for both the HT and regular hot end. This meant that if you used the FlashForge High Temp heat break, which screws into the heatsink with a length of PTFE tube that slides into it to bridge the gap from the top of the heatsink to the heat break, there was open space around the tube. You need an EXACT cut for the tube to connect the inside of the top of the heatsink to the heat break without any gaps and without making the tube flex. Inevitably, the tube would soften or be too long or just people would screw the heat break into the heatsink too far, and bend the tube. Minor bowing wasn't usually a problem, but sometimes it could kink and jam.

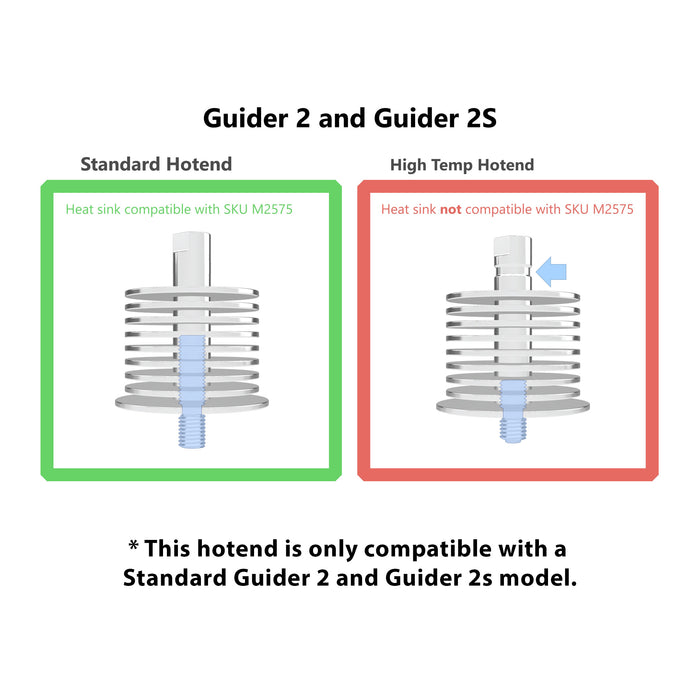

This Micro Swiss all metal hot end is designed to fit that heatsink and replace the stock heat break on the non HT hot end for the Guider 2/2s first version.

FlashForge made a new heatsink for the Guider 2s HT version with an opening just big enough to hold the PTFE tube. Cutting the right size became easier, since you could feel when the heat break was snug against the PTFE tube inside. You'll notice that the HT heat break end that goes into the heater block is shaped like the MS all-metal hot end heat break. FlashForge also released HT nozzles that are extended length like the standard temp nozzles, but instead of having room for the PTFE tube to slide into, it is just big enough for the filament. Along with this, FladhForge also release a new heater block that clamps the heating element better and has a groove down the center for some unknown reason. One other difference I noticed about this heater block is that it appears to be shaped upside down. That is, there's a slight recess around the threading for the nozzle and the heat break, but on this one, the recess (which should be for the nozzle) is at the top by the heat break inside of on the bottom for the nozzle. If you flip it over with the recess on the bottom, the thermistor screws into the opposite side (obviously) if you line it up properly to fit the air shroud. This means routing the thermistor wire up from the left side, between the servo sensor and the heatsink, to plug into the board. If you install the heating element properly, then those wires also have to follow the same path. Maybe I'm missing something here but I find it annoying.

You can find both heater blocks and both heatsinks at partsbuilt. They also carry the micro swiss hot end at the same price, as well as the nozzles, and just about every other part.

The new HT hot end for the Guider 2s HT can handle 300c even though it still has a (shorter) PTFE tube inside, because it ends in the heat break and not the nozzle. This eliminates some of the need for the micro swiss all metal hot end, but not all of it. Some materials work best in an all-metal hot end though. You do need to adjust your temperatures with an all metal hot end, and most people end up printing too hot, causing jamming. Another common mistake is using too large of a retraction setting. Using FlashPrint, most materials I use either a 0.1mm or 0.3mm retraction length at about 45mm/s. The melt zone is a little larger with an all metal hot end and is a more drastic transition to the cold end.

I have multiple full hot end assemblies for multiple needs. I found a plated copper nozzle that I like that works with the all metal heat break from micro swiss.

One thing most people don't do also is adjust the nozzle properly. You want to screw it in almost entirely. Screw it in entirely and then back it out about a quarter turn. Screw the heat break into the heater block until you feel it touch the nozzle. You'll want probably plyers and a nozzle socket for this next part. Preheat your hot end to the default 220. Once heated, screw the nozzle in snug against the heat break. This ensures no gap and avoids jamming that usually occurs when there's a slight gap there, since there's no PTFE tube going all the way to the nozzle.

I hope this review helps some people understand the changes.