Micro Swiss Bowden Dual Gear Extruder

Micro Swiss Bowden Dual Gear Extruder

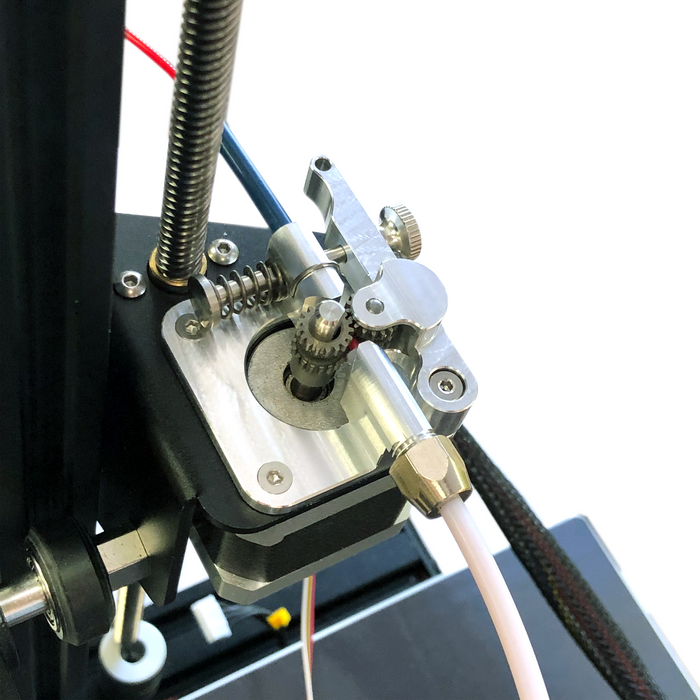

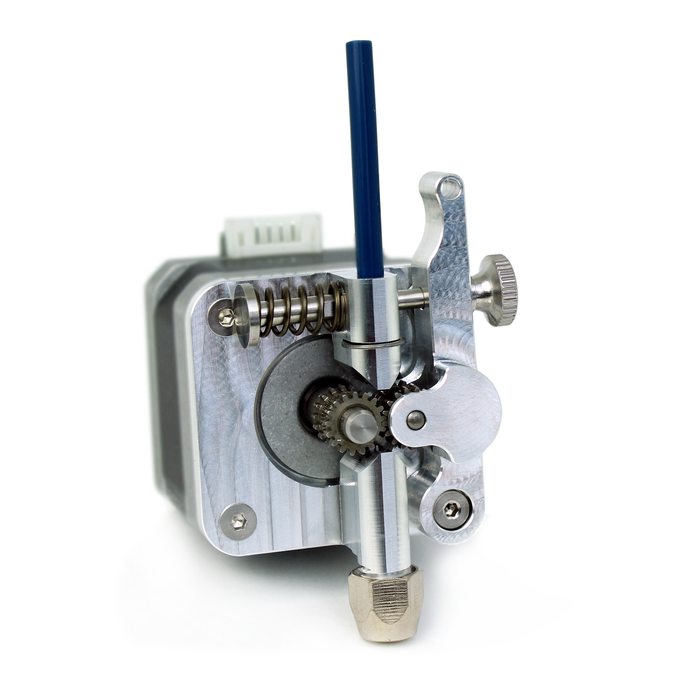

Micro Swiss Bowden Dual Gear Extruder features the same quality construction as our Direct Drive extruders. It is designed to be a bolt-on replacement to most of the Bowden extruder machines on the market.

Features:

- Dual-drive train

- Hardened tool steel, CNC precision cut gears

- Adjustable filament grip

- Easy filament loading

- Outstanding extrusion control

- E-steps value: 130

CNC Machined and Assembled in USA

Fits:

- Bowden extruder machines

- Ender 3, 5, 6, CR10, CR-10s Pro, CR-10S, CR6-SE, Tornado

- Fits NEMA 17 size stepper motors

Printable Filament Runout Sensor Bracket Download Links:

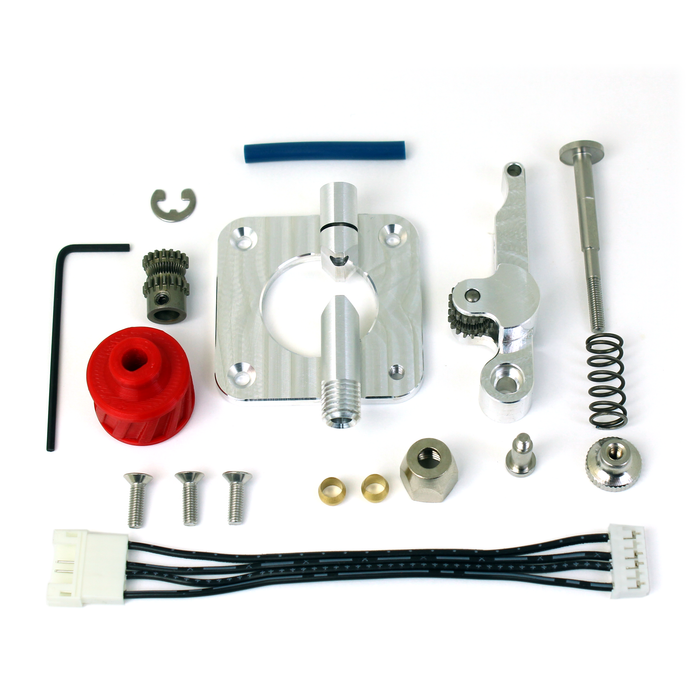

What's in the box

- 1x - Reverse polarity cable

- 3x - M3 x 8mm Motor Mounting Screws

- 1x - Capricorn Liner

- 1x - Spring Pin

- 1x - Spring

- 1x - Knob

- 1x - Main Extruder body

- 1x - E-Clip Retaining Ring

- 1x - Motor Gear

- 1x - Extruder Lever with gear

- 1x - Printed Extruder Knob

- 2x - Brass compression sleeve

- 1x -1.5mm Allen wrench

- 1x - Shoulder Pin

- 1x - Compression nut

Installation

Installation Instructions - Video

Printable Filament Runout Sensor Bracket Download Links: