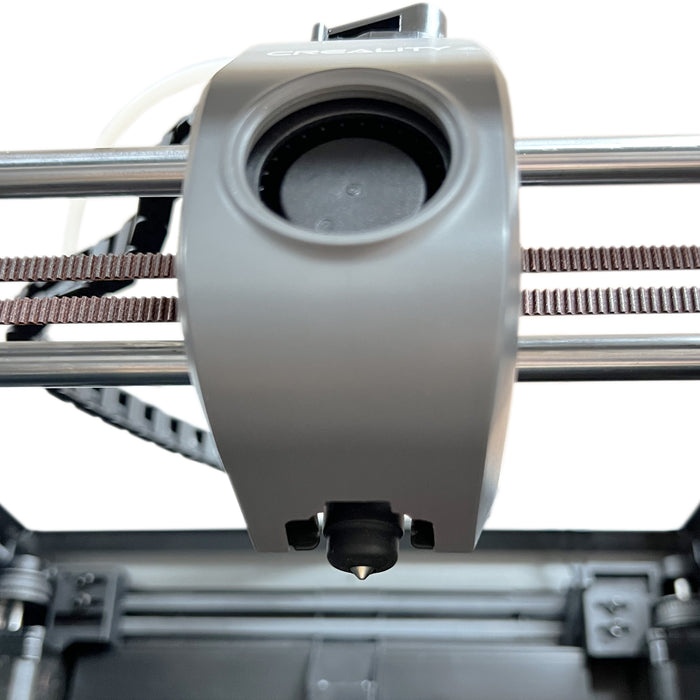

FlowTech™ Hotend for Creality K1 / K1 Max / K1C / K1 SE

The FlowTech™ Hotend is a new generation hotend line from Microswiss. Its unique design eliminates common hotend issues such as leaking nozzle seal and complex nozzle swaps.

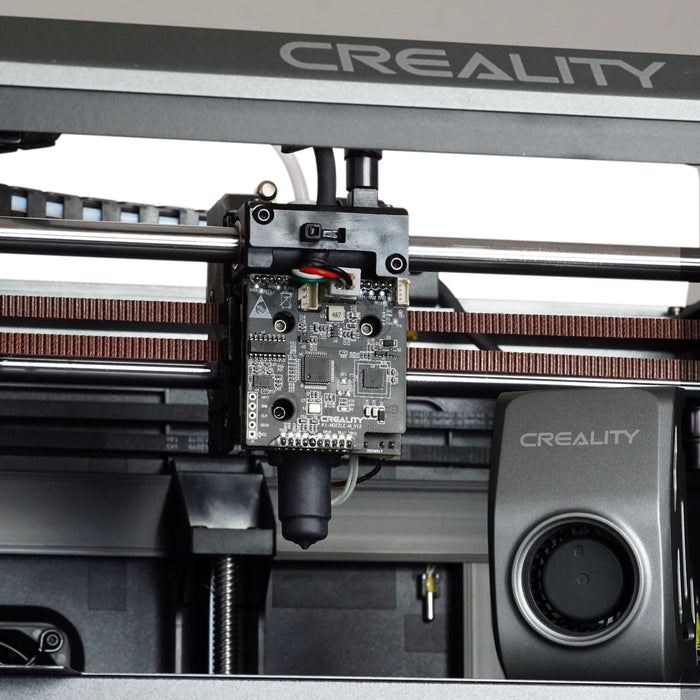

Keeping with our philosophy, the FlowTech hotend is designed to be an easy drop-in upgrade for each 3D printer model. This edition is designed for Creality K1. Stock z-height, build volume and firmware remains unchanged.

Made in USA by Microswiss

Features:

-

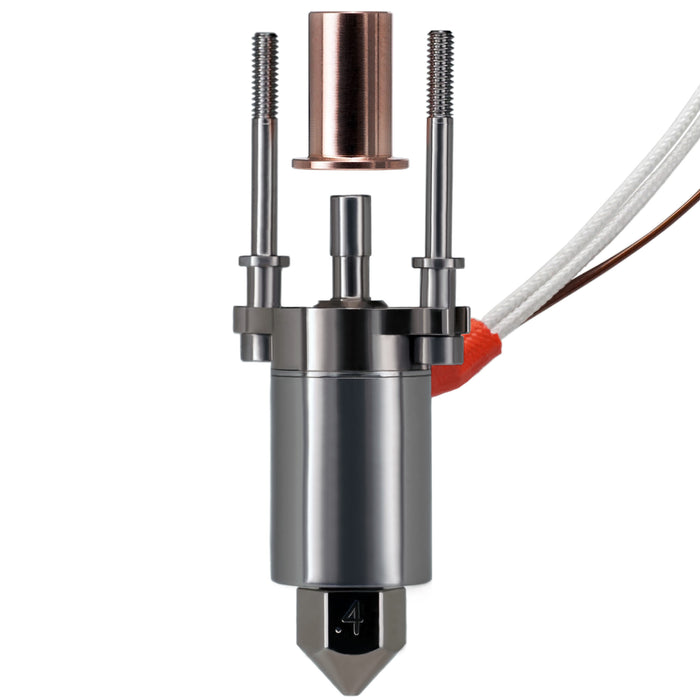

Leak-Proof Nozzle:

Tired of messy nozzle leaks that ruin your prints and waste filament? FlowTech Hotend combines nozzle and thermal break into one permanently sealed assembly that ensures a leak-proof hotend. -

Cold Nozzle Change:

Swapping out nozzles used to be a time-consuming and potentially hazardous task. With a FlowTech Hotend, nozzle changes are effortless, and there's no need for hot tightening, and you can do it with just one hand. -

High-Flow Characteristics:

Ceramic cylindrical heater and 28.6mm melt zone provides excellent volumetric flow rate. -

All-Metal Design:

Built to last! FlowTech hotend features an all-metal design that can handle most modern 3D printing filaments. The entire hotend is machined and assembled in-house, with quality control performed at multiple stages during the manufacturing process. At the end, each hotend undergoes a full thermal cycling test before it is packaged. -

300°C Max Temperature:

This hotend is rated at 300°C temperature with a properly tuned NTC thermistor for each specific printer. This particular edition is perfectly tuned for Creality K1 / K1 Max, K1C and K1 SE so no firmware changes are needed.

Fits:

- Creality K1

- Creality K1 Max

- Creality K1C

- Creality K1 SE

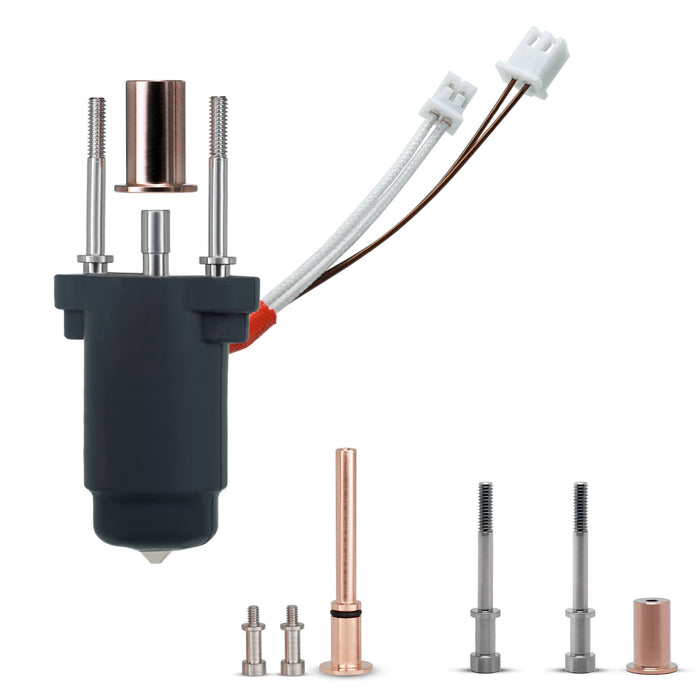

What's in the box

-

1x FlowTech™ Heater Core (24V - 60W)

-

1x FlowTech™ Brass Plated 0.4mm Nozzle

- 1x Silicon Sock

-

Hardware for Older K1 Printers

- 1x Copper Thermal Adapter

- 2x Titanium Mounting Screws

-

Hardware for New K1 Printers

- 1x Copper Thermal Adapter

- 2x Titanium Mounting Screws

- 1x Thermal Paste

- Adapter cables for newer Creality K1 PCBA breakout board

Documentation

- Installation Instructions