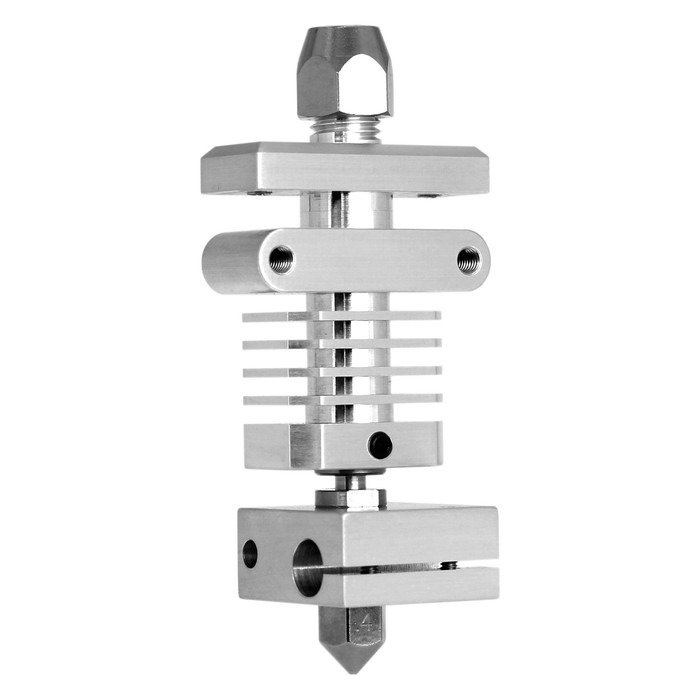

All Metal Hotend Kit for Creality CR-6 SE / CR-6 MAX / CR-10 Smart

This is an All Metal Hotend Kit for CR-6 SE Printers.

This is a drop-in All Metal Conversion kit for the CR-6 SE printers. It requires absolutely zero modification to your printer to install. Our uniquely designed cooling block eliminates the need for a thermal tube. By not having a separate thermal tube inside the cooling block, it allows for faster heat dissipation.

The thermal heat break is made from Grade 5 Titanium Alloy to provide excellent thermal isolation between the heater and the cooling block. Titanium is an extremely strong material and offers almost 3x lower thermal conductivity than stainless steel, creating a more defined melt zone.

Made in USA by Microswiss

Fits

- Creality CR-6 SE

- Creality CR-6 MAX

- Creality CR-10 Smart *Fan Adapter required

Installation Instructions Video by Embrace Making for CR-10 Smart

What's in the box

- Aluminum Cooling Block

- Grade 5 Titanium Heat Break

- Aluminum Heater Block

- Brass Plated MK8 .4mm Nozzle

- Silicone Sock

- Hardware kit

Installation

Installation Instructions - PDF

Installation Instructions by John at Tripod’s Garage - Video

Installation Instructions by By Daniel at ModBot - Video

Installation Instructions by Embrace Making for CR-10 Smart - Video

Extra Nozzles

A2 Hardened tool steel MK8 nozzles