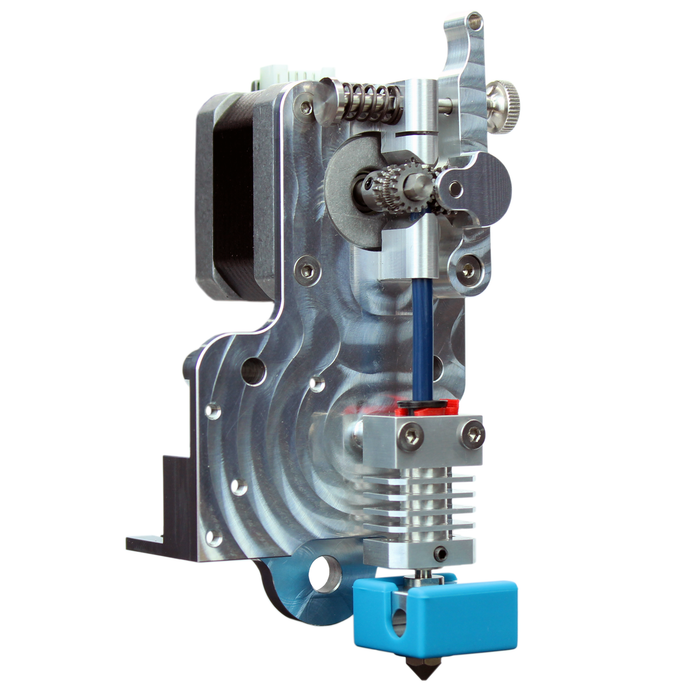

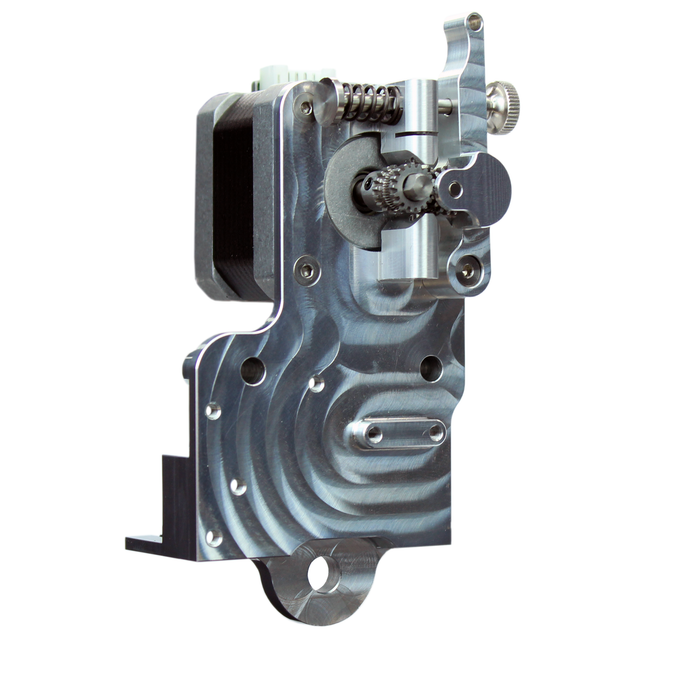

Micro Swiss Direct Drive Extruder for Creality CR-10 / Ender 3 Printers

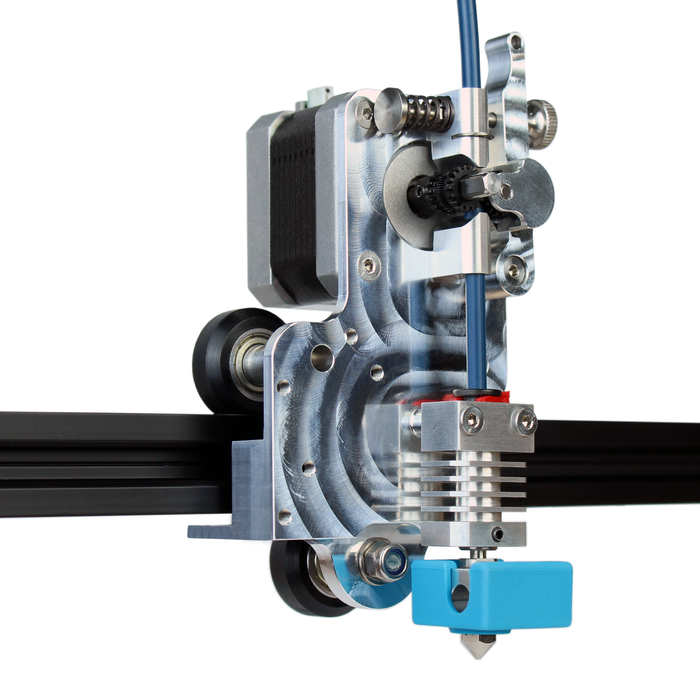

Micro Swiss Direct Drive Extruder is a drop in system for CR10 / Ender Printers

- No modification required, simple plug and play

- No printed brackets or sandwiches

Features:

- Dual-drive train

- Hardened tool steel, CNC precision cut gears

- Adjustable filament grip

- Easy filament loading

- Short, highly constrained filament path

- Prints flexible filaments with high speed and accuracy

- Outstanding extrusion control

- Lightweight aluminum body

Fits

- CR-10 (Will NOT directly fit CR10 V2, V3)

- CR-10-S5 *Fits with printable Fan Shroud

- CR-10-S4

- CR-10S

- CR-10S Pro V1 *Fits with printable Fan Shroud

- CR-10S Pro V2 *Fits with printable Fan Shroud

- CR-10 Max *Fits with printable Fan Shroud

- CR-10 MINI

- CR-20

- CR-20 Pro

- Ender 2

- Ender 3

- Ender 3 Max *Fits with printable Shroud Adapter

- Ender 3 Pro *Fits with printable Fan Shroud

- Ender 3 V2 *Fits with printable Fan Shroud

Installation Instructions Video by My Tech Fun for Ender 3 V2

Disclaimer:

We notice a recent extruder stepper motor update on Creality machines. Before ordering this kit, please check your extruder stepper motor. If your extruder motor gear is pressed in, you will need to purchase a new stepper motor to be able to complete the installation.

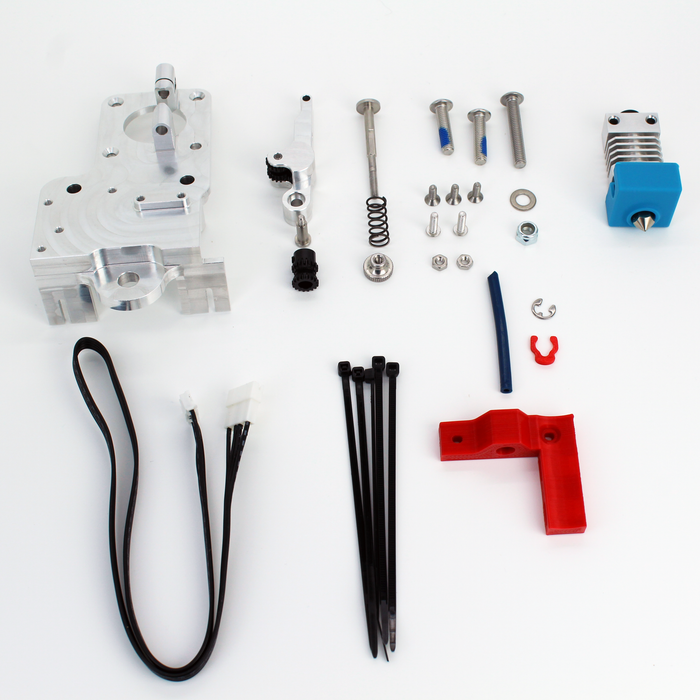

What's in the box

- Stepper motor and roller wheels are NOT included

- 1 x Micro Swiss All Metal Hotend (If option selected)

- 1 x Main Extruder body

- 1 x Extruder Lever

- 1 x Spring Pin

- 1 x Spring

- 2 x Gears

- 1 x Knob

- 1 x Shoulder Pin

- 2 x M5 20mm Nylon Patch Bolts

- 1 x M5 30 Bolts

- 1 x M5 Nylon Lock Nut

- 1 x M5 Washer

- 1 x Extension Cable

- 3 x M3 Motor Mounting Screws

- 2 x M3 Bolts

- 2 x M3 Nuts

- 5 x Zip Ties

- 1 x Printed Bracket

- 1 x Beveled Capricorn Liner

Installation

Installation Instructions - PDF

Installation Instructions By Daniel at ModBot - Video

Installation Instructions by My Tech Fun for Ender 3 V2 - Video

After the installation, X and Y origins will be off the bed.

Adjustments procedure will depend on a type of the firmware and the setup you are currently using.

Chose the setup you have:

Without any bed leveling probe installed

Leveling probe installed with generic or Creality Marlin Firmware

Leveling probe installed with TH3D Unified Firmware

Extra Nozzles

A2 Hardened tool steel MK8 nozzles