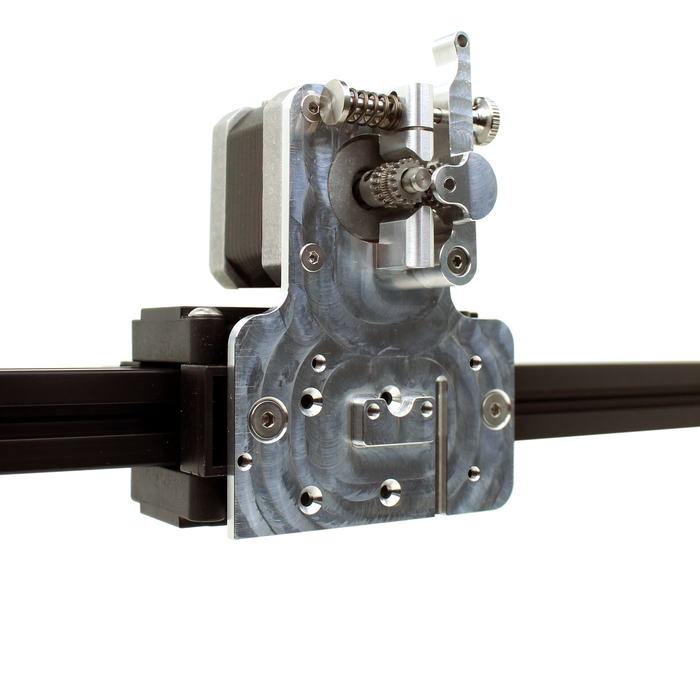

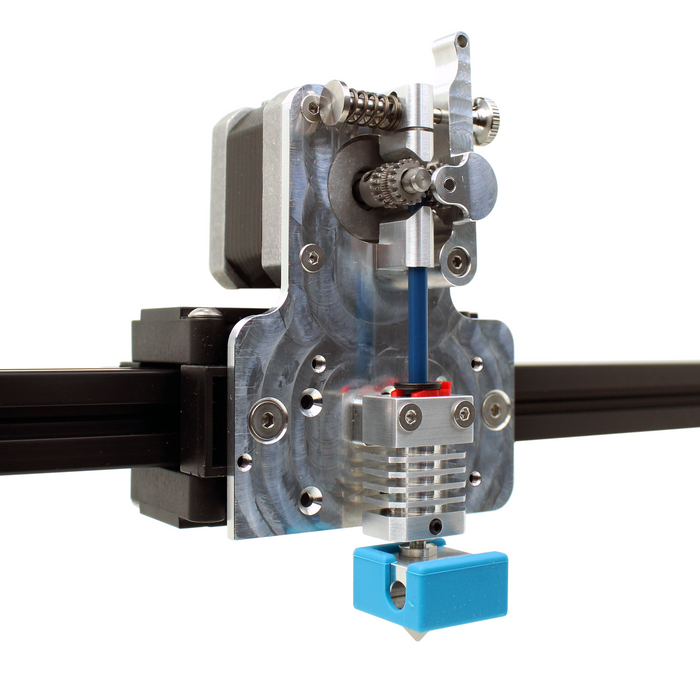

Micro Swiss Direct Drive Extruder for ExoSlide System

Original price

$ 57.75

-

Original price

$ 99.75

Original price

$ 57.75

$ 57.75

$ 57.75

-

$ 99.75

Current price

$ 57.75

SKU

Micro Swiss Direct Drive Extruder configured for ExoSlide System.

- No modification required, simple plug and play

- No printed brackets or sandwiches

Features:

- Dual-drive train

- Hardened tool steel, CNC precision cut gears

- Adjustable filament grip

- Easy filament loading

- Short, highly constrained filament path

- Prints flexible filaments with high speed and accuracy

- Outstanding extrusion control

- Lightweight aluminum body

Fits

- Printers with ExoSlide System

What's in the box

- Stepper motor, Linear Rail and Carriage Block are NOT included

- 1x Micro Swiss All Metal Hotend (If option selected)

- 1x Main Extruder body

- 1x Extruder Lever

- 1x Spring Pin

- 1x Spring

- 2x Gears

- 1x Tension Knob

- 1x Shoulder Pin

- 1x Extension Cable

- 3x M3 x .5 x 6mm Motor Mounting Screws

- 2x M4 x .7 x 16mm ExoSlide mounting screws

- 2x M3 x .5 x 10mm Screws

- 2x M3 x .5 Nuts

- 5x Zip Ties

- 1x Printed Bracket

- 1x Beveled Capricorn Liner

Installation

Instructions Instructions - PDF

Instructions Instructions By Daniel at ModBot - Video

Extra Nozzles

A2 Hardened tool steel MK8 nozzles

M2 Hardened High Speed Steel Nozzle MK8 nozzles