FlowTech™ Hotend for Sovol SV08

FlowTech™ Hotend for Sovol SV08

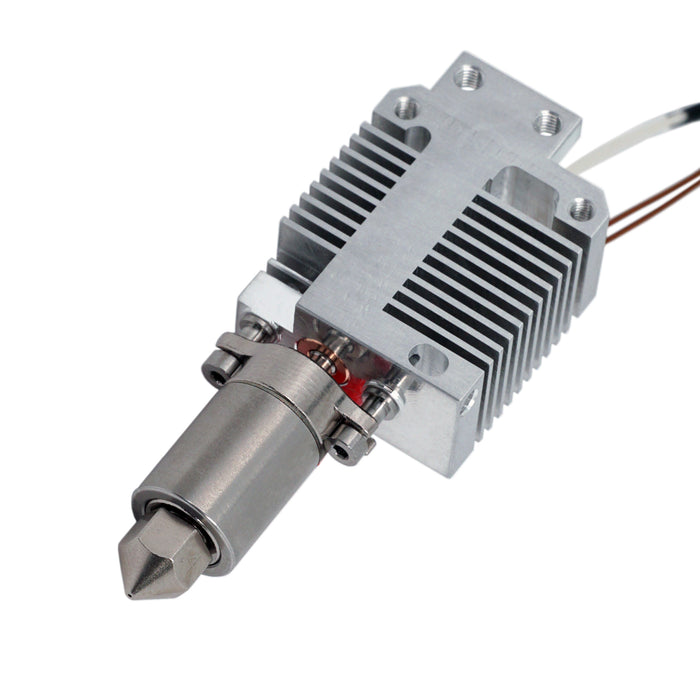

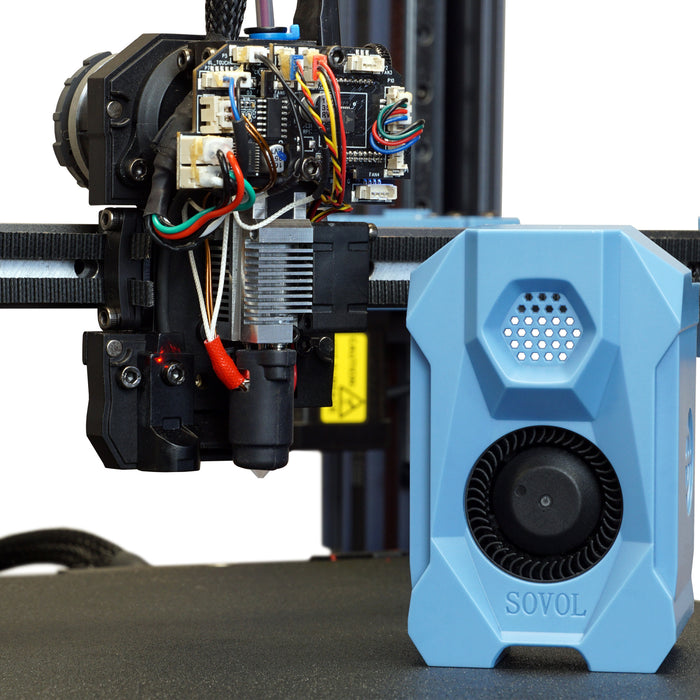

This kit comes with a plug and play Heater Core and thermistor, fully compatible with Sovol SV08 printer. Stock z-height, build volume and firmware remains unchanged.

By upgrading your Sovol SV08 to a FlowTech ecosystem, you can utilize a comprehensive range of FlowTech, leak-proof nozzles. These nozzles include the DiamondBack, CHT High Flow, and CM2 Hardened tip nozzles.

Made in USA by Microswiss

Features

-

Leak-Proof Nozzle:

Tired of messy nozzle leaks that ruin your prints and waste filament? FlowTech Hotend combines nozzle and thermal break into one permanently sealed assembly that ensures a leak-proof hotend. -

Cold Nozzle Change:

Swapping out nozzles used to be a time-consuming and potentially hazardous task. With a FlowTech Hotend, nozzle changes are effortless, and there's no need for hot tightening, and you can do it with just one hand. -

High-Flow Characteristics:

Ceramic cylindrical heater and 28.6mm melt zone provides excellent volumetric flow rate. -

All-Metal Design:

Built to last! FlowTech hotend features an all-metal design that can handle most modern 3D printing filaments. The entire hotend is machined and assembled in-house, with quality control performed at multiple stages during the manufacturing process. At the end, each hotend undergoes a full thermal cycling test before it is packaged. -

300°C Max Temperature:

This hotend is rated at 300°C temperature with a properly tuned NTC thermistor for each specific printer. This particular edition is perfectly tuned for Sovol SV08 so no firmware changes are needed.

Fits:

- Sovol SV08

What's in the box

-

1x FlowTech™ Heater Core (24V - 60W)

- 1x FlowTech™ Brass Plated 0.4mm Nozzle

- 1x Heatsink

- 2x Titanium Mounting Screws

- 1x Silicon Sock

Documentation

- Installation Instructions

-

- Video Guide:

By Daniel at ModBot

- Video Guide:

-

Volumetric Flow Rate Analysis