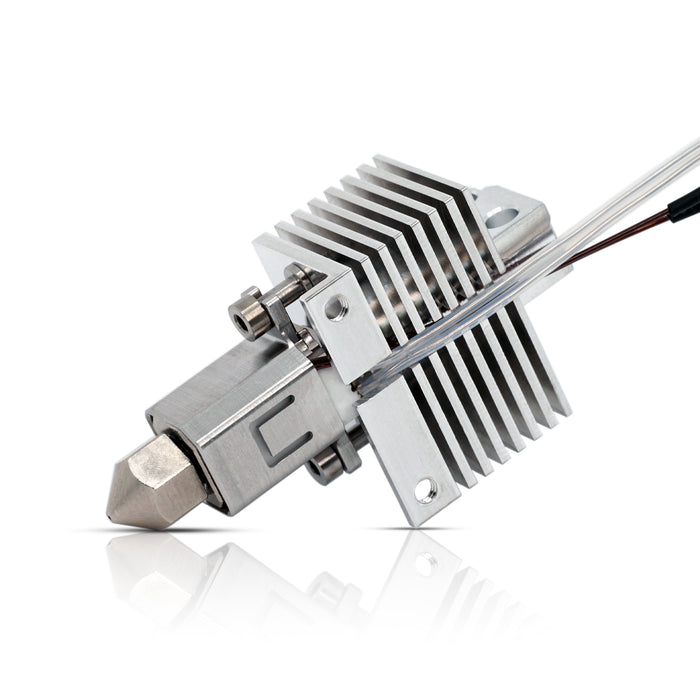

FlowTech™ Hotend for Bambu Lab X1 and P1 Printers

FlowTech™ Hotend for Bambu Lab Printers

Microswiss FlowTech Hotend is designed with advanced features for optimized performance. Paired with Bondtech CHT High Flow Nozzles, this hotend delivers up to 50 mm³/sec for ultra-fast printing without compromising quality. Installation is simple and plug-and-play, allowing you to integrate it seamlessly into your Bambu Lab Printers.

Made in USA by Microswiss

Fits:

- Bambu Lab X1C

- Bambu Lab P1S

- Bambu Lab P1P

What's in the box

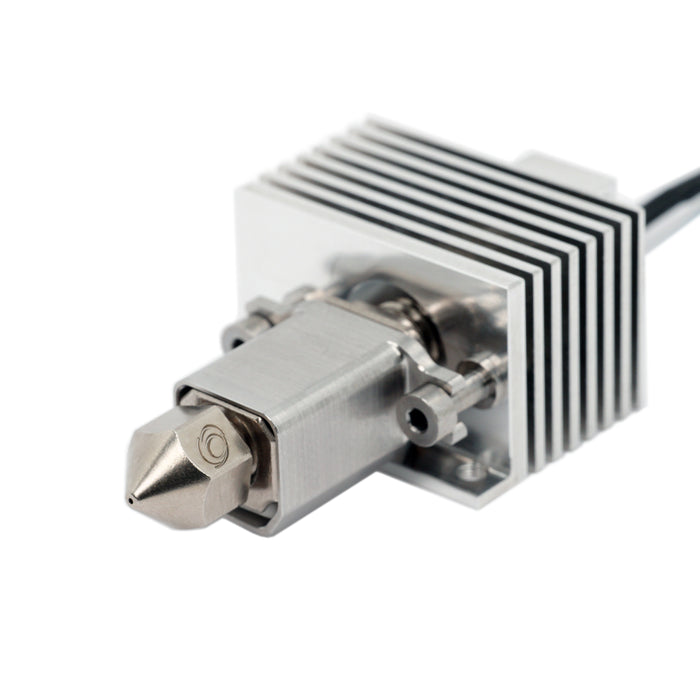

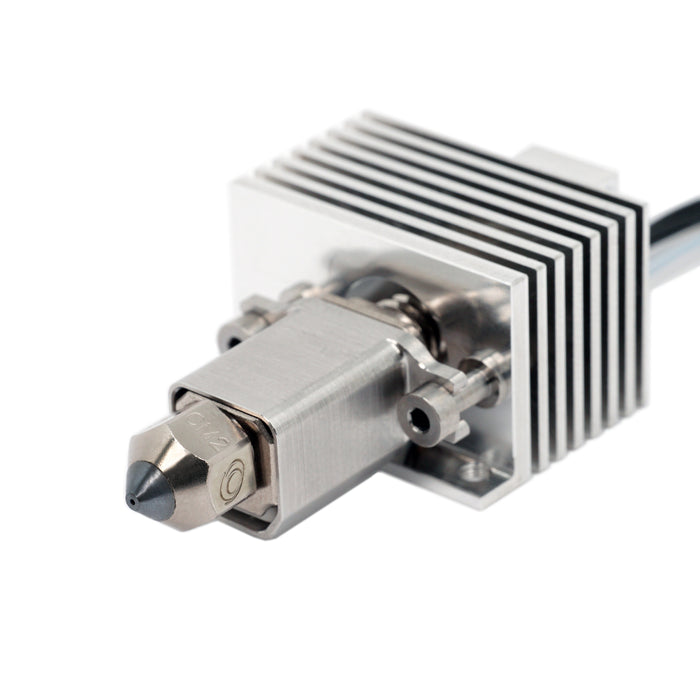

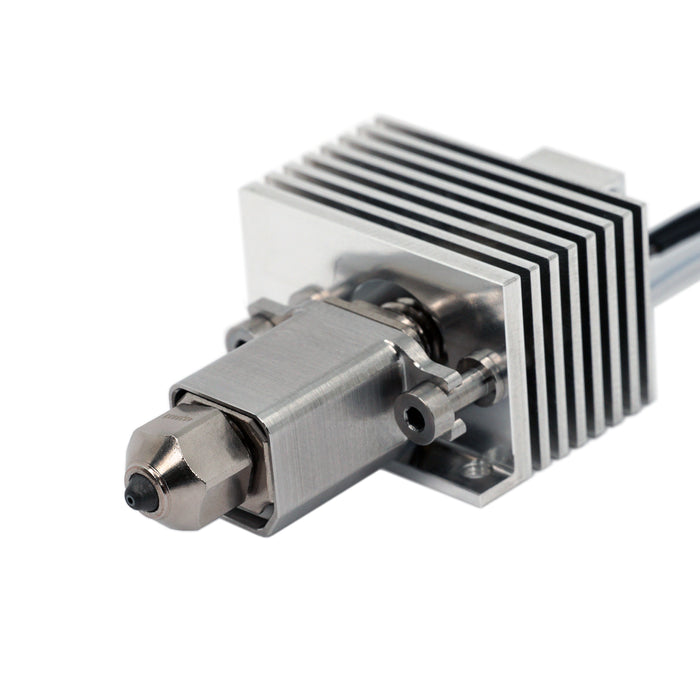

- 1x FlowTech™ Heater Core for Bambu Lab

- 1x Heatsink for Bambu Lab

- 2x Titanium heater core mounting screws

- 1x FlowTech 0.4mm Nozzle (CM2™, CHT, CM2™ CHT, DiamondBack)

- 1x Silicon Sock

- 2x Fan mounting shoulder screws

- 1x Printed Nozzle changing tool

Documentation

- Installation Instructions

- Video Guides:

- Other Documents