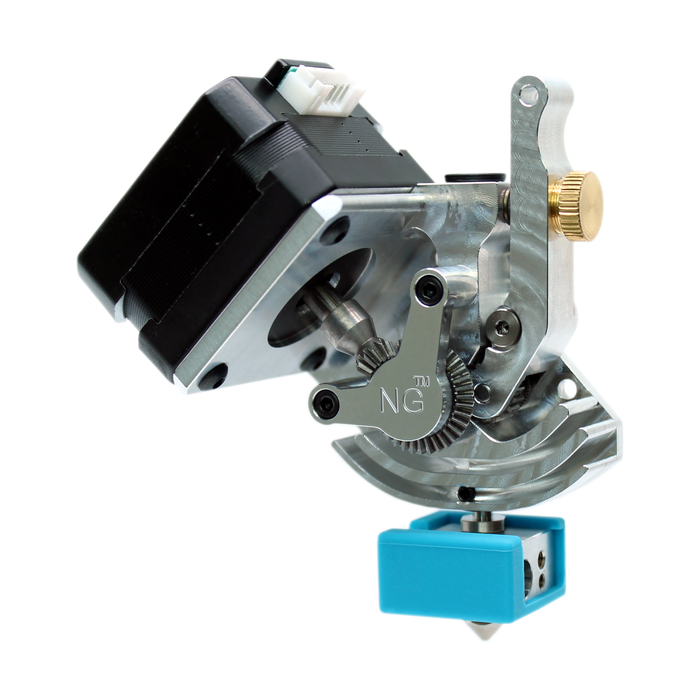

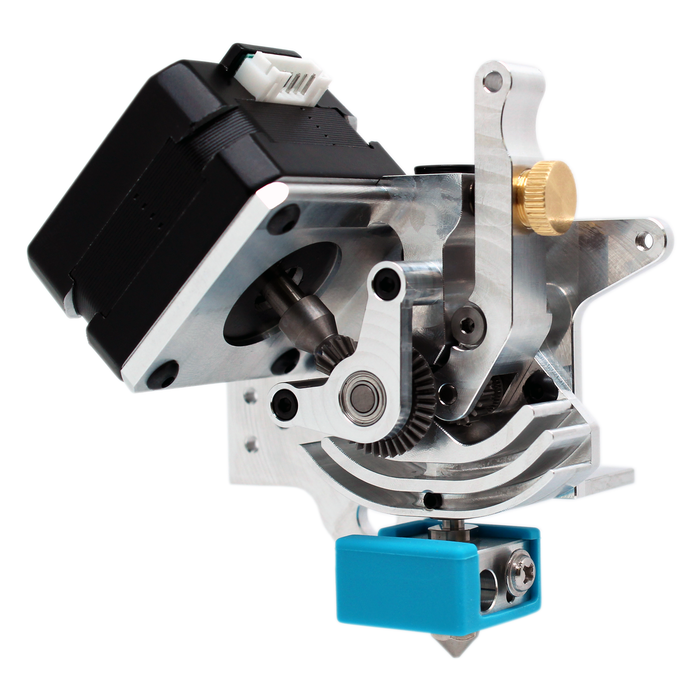

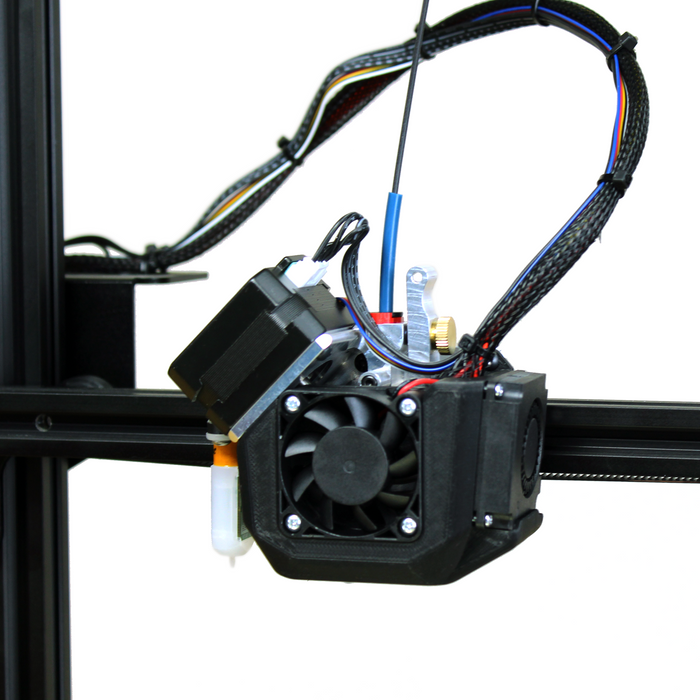

Micro Swiss NG™ Direct Drive Extruder for Creality CR-10 / Ender 3 Printers

Micro Swiss NG™ Direct Drive Extruder

This extruder overcomes the shortcomings of all current counterparts on the market, to create an optimal printing experience for everyone.

With the Bevel Gear design, we are able to achieve the industry shortest filament path (less than 41mm). The unique motor placement allows for highly compact, low overhang design. This further increases system rigidity.

Features:

- Lightweight

- 3:1 Gear ratio

- Adaptable to wide range of 3D Printers

- Hardened steel, precision cut Dual Gear drive

- Industry shortest, highly constrained, TwinClad XT™ plated filament path

- Bevel Gear system allows a low overhang extruder mount

- Integrated with a Micro Swiss All Metal Hotend

Made in USA by Micro Swiss

Fits

- CR-10

- CR-10s

- CR-10-S5

- CR-10-S4

- Ender 3

- Ender 3 Pro

- Ender 3 V2

What's in the box

- 1x Master Extruder Assembly

- 1x Adaptation plate

- 1x LDO Stepper motor - Motor Drawing

- 1x Fan Shroud

- 1x Custom extension cable

-

1x All Metal hotend (M2707-04)

- Thermal Break (M2593)

- Heater Block (M2587)

- Silicone Sock (M2588)

- MK8 Nozzle (M2549-04)

Hardware:

- 1x Eccentric nut

- 1x M5 x .8 x 30mm CAP SCREW

- 1x 5mm ID 10mm OD Washer

- 1x M5 x .8 Nylon Lock Nut

- 2x M5 x .8 x 20mm Nylon Patch CAP SCREWs

- 4x M2.2 x 8mm Thread Forming Screw for Plastic

- 4x M3 x 12mm Thread Forming Screw for Plastic

- 1x 7mm spanner wrench

- 1x 1.5mm Allen wrench

- 5x Zip Ties

Installation

PDF:

Installation Instructions - PDF

Video Guides:

By Daniel at ModBot

By John at Tripod’s Garage

By Chris at Chris's Basement

By Chris at Embrace Making

Downloads

Spare Nozzles

A2 Hardened tool steel MK8 nozzles

M2 Hardened High Speed Steel Nozzle MK8 nozzles